Switchon Deepinspect

AI Vision Inspection System for Manufacturing

Experience the future of manufacturing with SwitchOn’s DeepInspect, an AI-powered vision inspection system designed to optimize quality control. With an impressive ability to reduce quality costs by over 60% and achieve 100% compliance, DeepInspect sets a new standard in efficiency and precision.

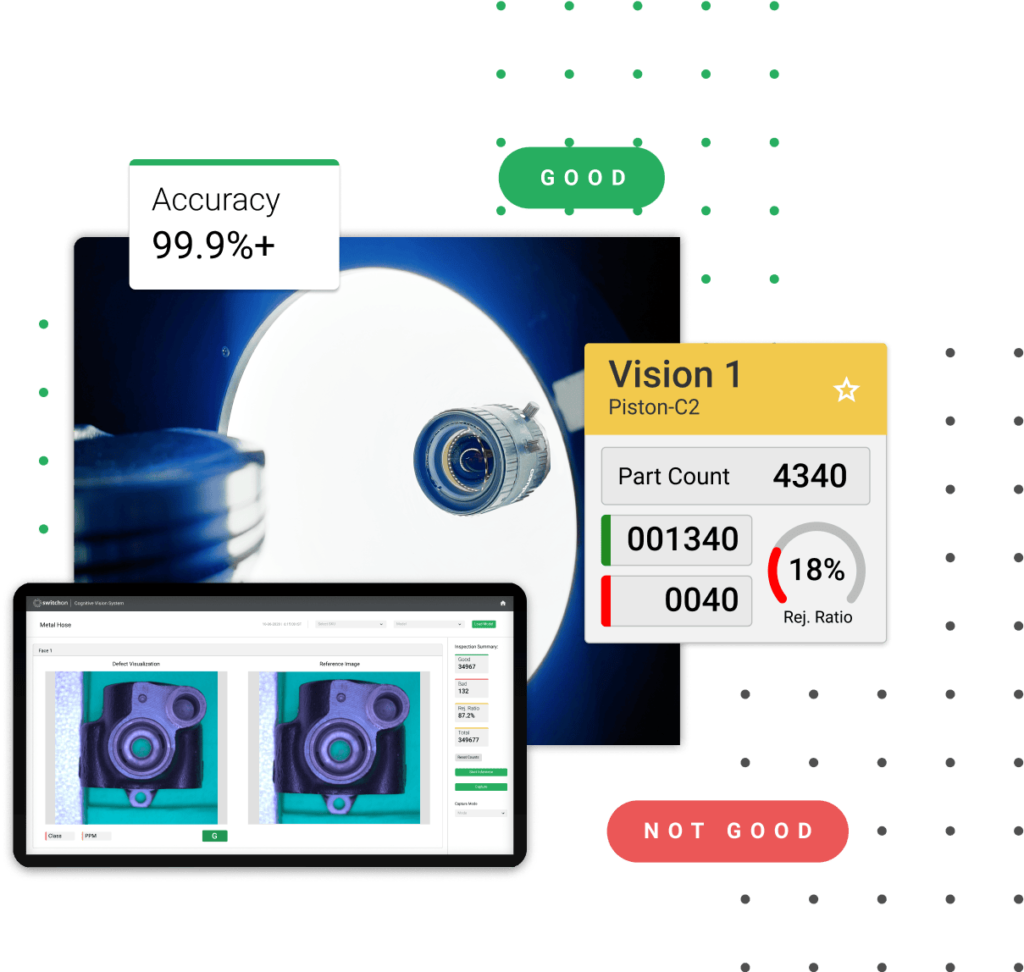

Train models within minutes using fewer than 200 good images, reaching 99.9%+ production-level accuracy. Ideal for automotive, consumer goods, and pharmaceutical industries, DeepInspect guarantees flawless inspection and minimal wastage. Transform your manufacturing process with SwitchOn DeepInspect, where innovation meets excellence.

SwitchOn by the Numbers

60%+ Reduction in Quality Cost

Automate the Quality Inspection to reduce quality costs by 60% & attain 100% internal and external compliance in quality control processes.

AI-Powered Inspection with <200 Images

Train new models within minutes with <200 Good Images and reach extreme accuracies. We do not need any defect images for training and zero line stoppage.

99.9%+ Production-Level Accuracy

With a one-click platform, you can drastically reduce false positives to attain near-perfect accuracy and reduce wastage in complex surface defects and artwork issues.

Book a free demo or consultation of this product:

-Talk to a 3D expert

-See Switchon DeepInspect in action

-Be assured that Switchon DeepInspect fits for you

Benefits of AI Vision Inspection System

- Improved Accuracy and Precision – AI vision inspection systems like

- DeepInspect achieve exceptional accuracy, detecting defects as small as 50 microns.

- Cost Reduction – By automating the inspection process, AI systems significantly reduce the cost of quality control.

- Enhanced Efficiency – AI vision inspection systems operate at high speeds, inspecting hundreds of parts per minute.

- Consistent Quality Control – AI systems provide consistent and unbiased inspection, eliminating the variability inherent in manual inspections.

- Rapid Deployment and Scalability – AI vision systems can be trained and deployed quickly, often within minutes, using fewer than 200 good images.

Advanced AI Technology That Transforms Quality Control

SwitchOn DeepInspect harnesses cutting-edge AI technology to deliver unparalleled accuracy and efficiency in quality inspection. From detecting microscopic defects to ensuring compliance with industry standards, DeepInspect sets a new benchmark in manufacturing excellence.

DeepInspect Use Cases

SwitchOn DeepInspect excels in a variety of inspection scenarios, ensuring high precision and efficiency in diverse manufacturing environments. Speak with a Rev1 specialist to discover how DeepInspect can help optimize product quality control

Machining Inspection

Stamping Inspection

Die-Casting Inspection

Assembly Verification

Packaging Inspection

Injection Molding Inspection

Bottle Inspection

Vial Inspection

Bearing Inspection

Soap Inspection

Deploy DeepInspect in 3-Steps

The screenshots detail a three-step process for deploying an AI-driven defect detection system named DeepInspect. The steps are:

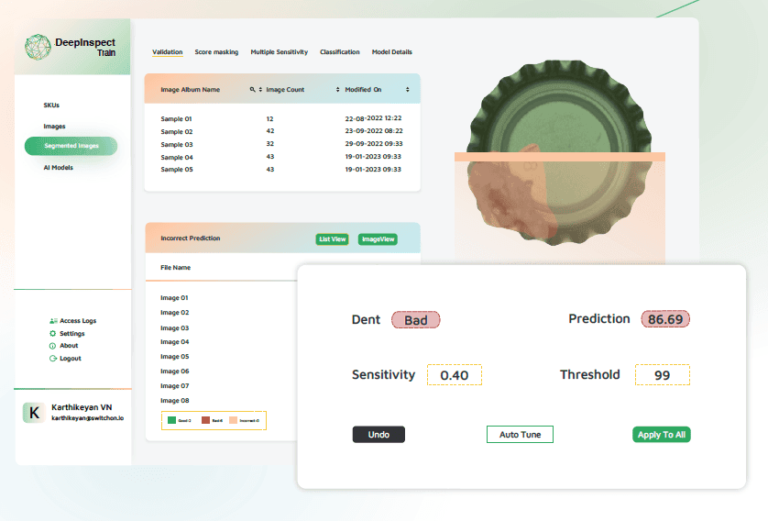

Train

The first step involves training the AI models by uploading images of non-defective products. With just 100 images, the system can reach an accuracy of 99.9%, making it user-friendly and efficient. It emphasizes ease of use with one-click training from the comfort of an office, reducing the necessity for extensive technical knowledge.

Inspect

This stage uses the trained AI models to inspect and identify defects in products at high speeds. The technology can handle complex surface defects, particularly on reflective surfaces. The system operates independently of high-speed internet or other external infrastructure, ensuring that data remains within the manufacturing facility, which enhances data security.

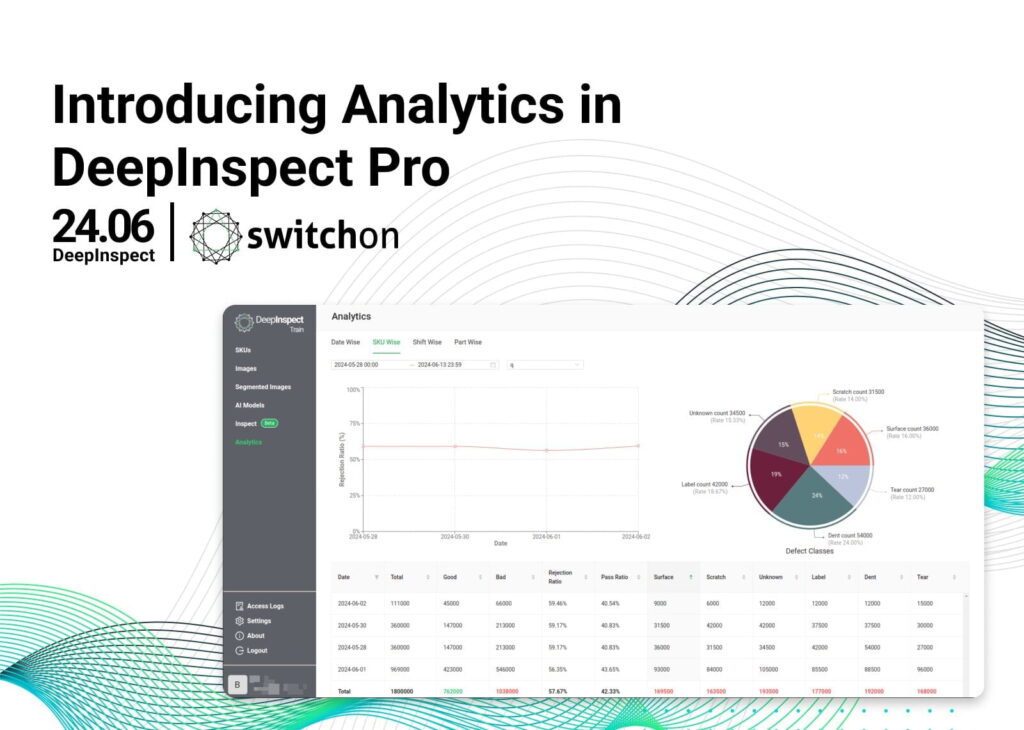

Analyze

The final step allows users to view and analyze the performance metrics of their manufacturing lines from anywhere. It integrates with existing ERP/MES systems and provides detailed analytics that help in identifying the root causes of manufacturing issues. This feature enables decision-makers to monitor and improve production efficiency remotely.