Kings 3D SLA 800 Pro

Understanding SLA 3D Printing Technology

The KINGS 800Pro utilizes advanced SLA technology to create precise and durable 3D models. The process begins by focusing a laser beam onto the surface of a photocurable resin. The laser solidifies the resin layer by layer, following a pre-programmed pattern derived from a CAD model. As each layer is cured, the build platform lowers incrementally, allowing the next layer to be formed. This additive manufacturing process results in highly accurate and detailed 3D objects.

Book a free demo or consultation of this product and get your sample parts printed:

-Talk to a 3D expert

-See Kings SLA in action

-Be assured that Kings 800Pro fits for you

Technical Principle Behind the KINGS 800Pro

The KINGS 800Pro’s technical superiority lies in its intelligent scanning system, high-speed laser, and robust construction. By automatically adjusting the laser spot size and power based on the model’s requirements, the printer ensures consistent quality across every layer. The use of a full marble structure and high-stiffness light recoater further enhances stability and precision, making the KINGS 800Pro an ideal solution for industrial applications.

Printing Capabilities

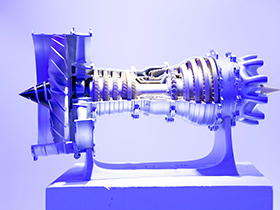

Versatile Applications of the Kings 800Pro 3D Printer

The Kings 800Pro 3D printer is a versatile tool, ideal for producing accurate prototypes, functional automotive parts, and intricate designs in art and craft. In the automotive sector, it ensures high-precision, reliable production of parts that meet industry demands. Artists can bring detailed visions to life, crafting sculptures and jewelry with precision that traditional methods can’t match. The footwear industry benefits from its ability to quickly produce detailed shoe molds, enabling rapid prototyping and faster product iterations for personalized designs.

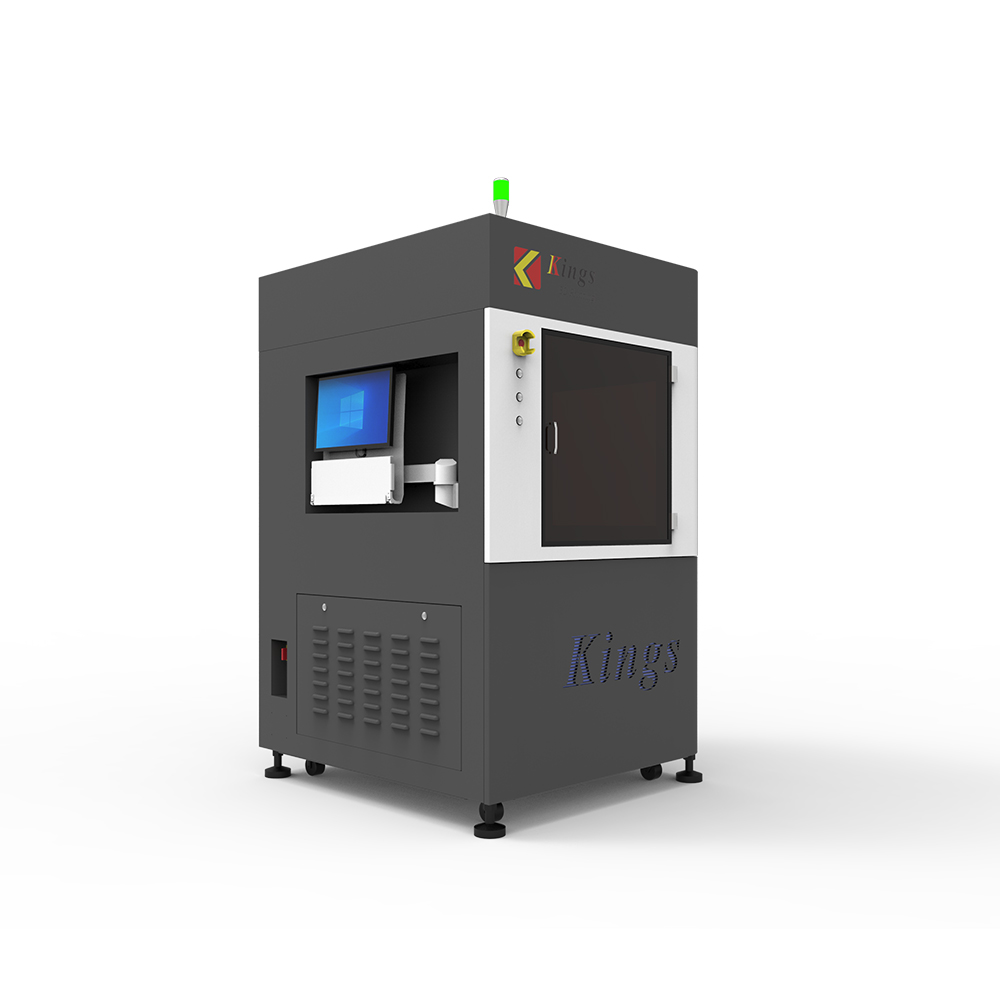

Meet Kings 800Pro Industrial SLA 3D Printer

Key Features of the Kings 3D SLA 800

High Precision

The Kings 3D SLA 800 is equipped with imported ball screws and linear guide rails that ensure remarkable printing accuracy, achieving up to 0.01mm precision. This level of detail is essential for industries where even the smallest variation can impact the performance of a prototype or product, such as in medical, automotive, or aerospace applications. The machine’s mechanical components maintain stable and smooth movements, ensuring that every layer of the printed object aligns perfectly, producing fine and detailed results.

Fast Printing Speed

The Kings 3D SLA 800 is designed for speed without compromising quality. It supports rapid printing, making it possible to produce both prototypes and final products in a fraction of the time traditional methods would take. This efficiency makes it particularly useful for batch production and projects requiring quick turnaround times, helping companies reduce lead times and move products from the design phase to market more quickly. Whether you’re producing single items or larger production runs, the SLA 800 is capable of handling it efficiently.

Versatile Resin Choices

One of the standout features of the Kings 3D SLA 800 is its compatibility with a wide range of photopolymer resins. These resins vary in terms of rigidity, color, clarity, and temperature resistance, allowing users to select the right material for their specific needs. Whether you require a rigid material for automotive parts, a clear resin for intricate jewelry designs, or a heat-resistant material for industrial applications, the SLA 800 can accommodate these requirements. This flexibility makes it suitable for diverse industries including engineering, art, and medical fields.

Advanced Technology

The Kings 3D SLA 800 incorporates advanced components such as a German-made galvanometer scanner and a US-sourced laser device. These high-quality devices ensure precise laser movement and control, which is critical in achieving the fine detail and accuracy needed in industrial-grade 3D printing. The galvanometer scanner precisely directs the laser beam onto the resin, while the laser device solidifies the resin at exact points, layer by layer. This combination of technologies enables the machine to deliver top-tier results consistently, even with complex models.

Variable Light Spot

The printer is equipped with a variable light spot feature, which allows the machine to adjust the laser beam’s size to cover a larger area when needed. This results in a faster printing process without compromising detail. For intricate parts, the light spot can be minimized to ensure precision, while for larger, less detailed areas, the light spot can be increased to speed up production. This adaptability allows for both fine detail and efficiency, ensuring that the printing process is as fast as possible without losing accuracy.

User-Friendly Software

The Kings 3D SLA 800 comes with proprietary control software designed for simplicity and ease of use. The interface is visual and intuitive, allowing operators to quickly set up and manage the printing process, even for complex jobs. The software provides control over all aspects of the printing process, including laser settings, layer height, and resin selection. It also supports a wide range of file formats from popular 3D modeling software, ensuring compatibility with existing workflows. This user-friendly approach minimizes the learning curve and allows users to focus on creating high-quality prints.

Kings 3D SLA 800 Specs

| BASIC INFORMATION | |

| Max Printing Size | 800*800*500mm |

| Machine Size | 140cm(W)*149cm(D)*243cm(H) |

| Rated Power Consumption | 1.8KVA |

| Machine Weight | 1900kg |

| LASER SYSTEM | |

| Laser Type | Solid-state frequency tripled Nd: YV04 |

| Wavelength | 355nm |

| Power | Resin Surface Power≥ 300 mW |

| OPTICAL & SCANNING SYSTEM | |

| Scanning Mode | Germanic galvanometer scanner |

| Variable Beam System | Galvo/Closed-loop |

| Beam Size (diameter @1/e2) | 0.075-0.8mm (Variable Beam) |

| Max Scanning Speed | 15.0 m/s |

| RECOATING SYSTEM | |

| Main Sturcture | Marble recoater frame, marble elevator holder and marble scanning system base |

| Coating Mode | Intelligent position vacuum recoating |

| Vertical Resolution Ratio | 0.0005mm |

| Repeat Positioning Accuracy | ±0.01mm |

| Layer Thickness | 0.05mm~0.25mm |

| Accuracy | L≤150mm, ±0.15mm; L>150mm, ±0.15%*L |

| CONTROL SOFTWARE | |

| Motion Control System | Closed-loop |

| Machine Control Software | KINGS 3D control software |

| Input Data File Format | STL/SLC |

| Operating System | Windows 7/10 |

| Network Type and Protocol | Ethernet,TCP/IP |

| INSTALLATION CONDITION | |

| Electrical Requirement | 200-240VAC 50/60Hz, single-phase,10A |

| Ambient Temperature | 20-26ºC (72-79℉) |

| Relative Humidity | <40%,non-condensing |

| First Tank Resin | 500kg |

| WARRANTY | |

| Machine | Two years |

| Laser | Two years |