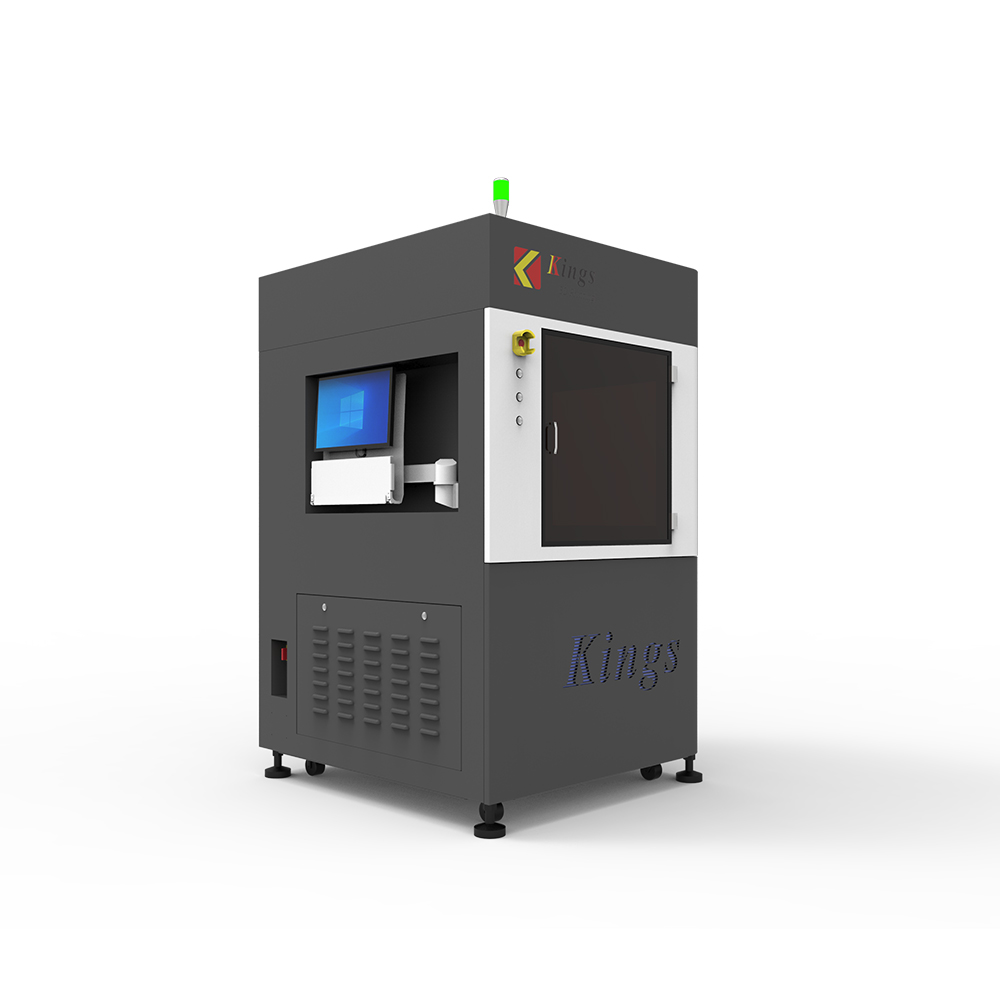

Kings 3D SLA 1000 Pro

The KINGS 1000Pro is a top-tier industrial SLA 3D printer engineered for precision and high efficiency in large-scale resin printing. With an impressive build volume of 1000 x 1000 x 600 mm, it is ideally suited for industries requiring the production of detailed and reliable 3D printed components on a larger scale.

Featuring a sophisticated triple-laser system and a German galvanometer scanner, the KINGS 1000Pro delivers exceptional detail and speed across a wide range of applications. Its durable construction, including a full epoxy granite structure and a high-stiffness light recoater, ensures enhanced stability and accuracy, making it a dependable solution for extended, high-performance operations.

Perfect for industries such as automotive, aerospace, and product design, the KINGS 1000Pro combines state-of-the-art technology with industrial-grade durability, guaranteeing consistent, high-quality results on every project.

Understanding SLA 3D Printing Technology

The KINGS 1000Pro harnesses cutting-edge SLA (Stereolithography) technology to produce highly detailed and durable 3D models. This process works by directing a focused UV laser onto a vat of liquid resin, solidifying it layer by layer as per a CAD design. With each pass of the laser, a new layer is cured and the platform lowers incrementally, creating an intricate three-dimensional object. This method allows for exceptional precision and a smooth finish, making it ideal for complex prototypes and final parts in various industries.

Book a free demo or consultation of this product and get your sample parts printed:

-Talk to a 3D expert

-See Kings SLA in action

-Be assured that Kings 1000Pro fits for you

Technical Principle Behind the KINGS 1000Pro

The KINGS 1000Pro uses Stereolithography (SLA) technology, where a 355nm UV laser cures liquid resin layer by layer to create 3D objects. The laser selectively hardens the resin based on a CAD model, and after each layer solidifies, the build platform lowers to expose the next layer for curing. Controlled by a closed-loop system, this process ensures precision and accuracy. The marble recoater frame and elevator holder provide stability, preventing deformation and maintaining high printing precision. This technology is ideal for creating detailed, high-quality prototypes and large-scale production.

Printing Capabilities

The KINGS 1000Pro sets a new standard in industrial 3D printing. Its advanced triple-laser system offers dynamic laser control, allowing users to optimize beam size and power for rapid production or intricate detail. Its intelligent scanning system automatically adjusts printing parameters for different layers, ensuring consistent quality and superior surface finishes, making it ideal for applications where precision is paramount.

Built with high-precision components like the Optowave laser and Scanlab galvanometer, the KINGS 1000Pro guarantees durable and accurate performance even in demanding environments. Its robust epoxy granite structure minimizes vibrations, ensuring stability and consistent high-quality output. The printer’s large build volume of 1000 x 1000 x 600 mm enables the production of large parts in a single print, while its efficiency in batch printing smaller parts makes it a versatile tool for high-throughput industrial applications.

In addition to its technical prowess, the KINGS 1000Pro offers exceptional flexibility, allowing users to easily switch between different printing materials to meet specific project requirements. This adaptability makes it suitable for various industries, from automotive and aerospace to product design and art, providing a reliable solution for complex and demanding production challenges.

Meet The KINGS 1000Pro 3D Printer.

Versatile Applications of the Kings 1000Pro 3D Printer

The KINGS 1000Pro is a powerful tool for creating large-scale, high-precision prototypes, functional industrial parts, and intricate designs across a wide range of industries. In automotive and aerospace, it delivers reliable, detailed production that meets rigorous standards. Artists can also leverage its precision for sculpting intricate art pieces, while manufacturers benefit from its speed and accuracy in producing molds and functional prototypes. With its capacity for continuous, high-quality output, the KINGS 1000Pro excels in demanding production environments.

Key Features of the Kings 3D SLA 1000 Pro

High-Precision Printing

The KINGS 1000Pro delivers unparalleled precision in 3D printing. With an adjustable laser spot size ranging from 0.075mm to 0.8mm, it ensures fine details and smooth surfaces in every print. This capability makes it ideal for industries that require accuracy, such as automotive, aerospace, and medical applications, where even the smallest deviation can be critical.

Large Build Volume

With a maximum printing size of 1000 x 1000 x 600 mm, the KINGS 1000Pro excels at producing large-scale prototypes and functional parts in a single print. This capability reduces the need for part assembly and allows manufacturers to work on larger projects without size limitations, making it perfect for automotive body components, large architectural models, or industrial machinery parts.

Advanced Laser Technology

Equipped with a 355nm UV laser from Optowave, a renowned US brand, the KINGS 1000Pro provides reliable and consistent performance. The laser ensures precise curing of each resin layer, achieving high levels of detail and durability in the printed models. With a laser power exceeding 300mW, the machine supports fast, efficient layer-by-layer solidification, ensuring higher productivity without compromising quality.

Full Marble Structure for Stability

The KINGS 1000Pro features a full marble structure, including the recoater frame, elevator holder, and scanning system base. Marble is naturally stable and resistant to deformation, ensuring that the laser system remains in precise alignment throughout the printing process. This structure enhances the printer’s overall accuracy and longevity, especially during long, continuous print jobs.

High-Speed Scanning for Efficiency

Thanks to its high-speed laser scanning system, capable of reaching speeds of up to 18m/s, the KINGS 1000Pro significantly reduces print times. This efficiency boost, combined with the printer’s ability to handle large builds, makes it ideal for industries where both speed and precision are essential, such as rapid prototyping and production tooling.

Custom Software for Enhanced Workflow

The KINGS 1000Pro is powered by KSBuilder 198, a proprietary software designed specifically for this machine. This software optimizes the printing process, ensuring smooth communication between design files and the printer. It supports common formats like STL and SLC and provides a user-friendly interface that allows operators to manage complex prints with ease. KSBuilder 198 also offers continuous updates, ensuring the software remains at the cutting edge of the industry.

Kings 3D SLA 1000 Specs

| BASIC INFORMATION | |

| Max Printing Size | 1000*1000*600mm |

| Machine Size | 160cm(W)×170cm(D)×243cm(H) |

| Rated Power Consumption | 1.8KVA |

| Machine Weight | 2600kg |

| LASER SYSTEM | |

| Laser Type | Solid-state frequency tripled Nd: YV04 |

| Wavelength | 355nm |

| Power | Resin Surface Power≥ 300 mW |

| OPTICAL & SCANNING SYSTEM | |

| Scanning Mode | Germanic galvanometer scanner |

| Variable Beam System | Galvo/Closed-loop |

| Beam Size (diameter @1/e2) | 0.085-0.8mm(Variable Beam) |

| Max Scanning Speed | 18.0m/s |

| RECOATING SYSTEM | |

| Main Sturcture | Marble recoater frame, marble elevator holder and marble scanning system base |

| Coating Mode | Intelligent position vacuum recoating |

| Vertical Resolution Ratio | 0.0005mm |

| Repeat Positioning Accuracy | ±0.01mm |

| Layer Thickness | 0.05mm~0.25mm |

| Accuracy | L≤150mm, ±0.15mm; L>150mm, ±0.15%*L |

| CONTROL SOFTWARE | |

| Motion Control System | Closed-loop |

| Machine Control Software | KINGS 3D control software |

| Input Data File Format | STL/SLC |

| Operating System | Windows 7/10 |

| Network Type and Protocol | Ethernet,TCP/IP |

| INSTALLATION CONDITION | |

| Electrical Requirement | 200-240VAC 50/60Hz, single-phase,10A |

| Ambient Temperature | 20-26ºC (72-79℉) |

| Relative Humidity | <40%,non-condensing |

| First Tank Resin | 880kg |

| WARRANTY | |

| Machine | Two years |

| Laser | Two years |