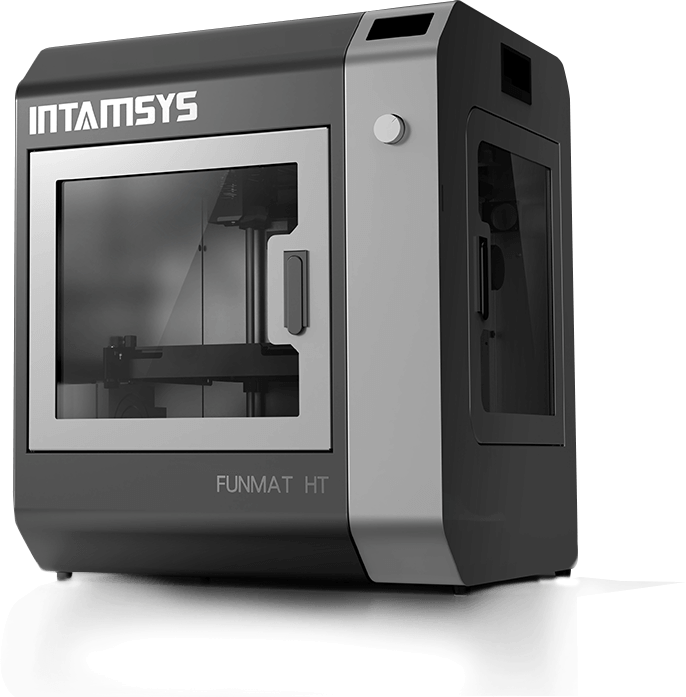

Funmat HT

The Intamsys Funmat HT is a cutting-edge, industrial-grade 3D printer engineered for high-temperature applications and professional use. Designed to handle demanding materials such as PEEK, ULTEM, and PEI, this robust FDM printer provides unmatched reliability, precision, and versatility. Whether you’re a small business or a large manufacturer, the Funmat HT offers the power and performance needed to create durable, complex parts with excellent mechanical properties. Featuring advanced thermal controls, swappable nozzles, and an intuitive interface, it’s the ideal solution for industries requiring high-performance materials, including aerospace, automotive, and medical fields.

Print Quality

The Intamsys Funmat HT delivers exceptional precision with a layer resolution as fine as 50 microns. Its single-extrusion system ensures high-quality prints, offering impressive accuracy for both detailed and complex geometries. With support for swappable nozzles ranging from 0.1 to 0.8 mm, it strikes the perfect balance between speed and detail, making it ideal for a wide variety of applications. The advanced thermal management, including the heated build chamber and bed, allows for smooth, warp-free finishes, particularly with high-performance materials such as PEEK, PEI, and PPSU. This makes the Funmat HT an excellent choice for industries demanding precision and material strength.

Book a free demo or consultation of this product and get your sample parts printed:

-Talk to a 3D expert

-See Intamsys in action

-Be assured that FUNMAT HT fits for you

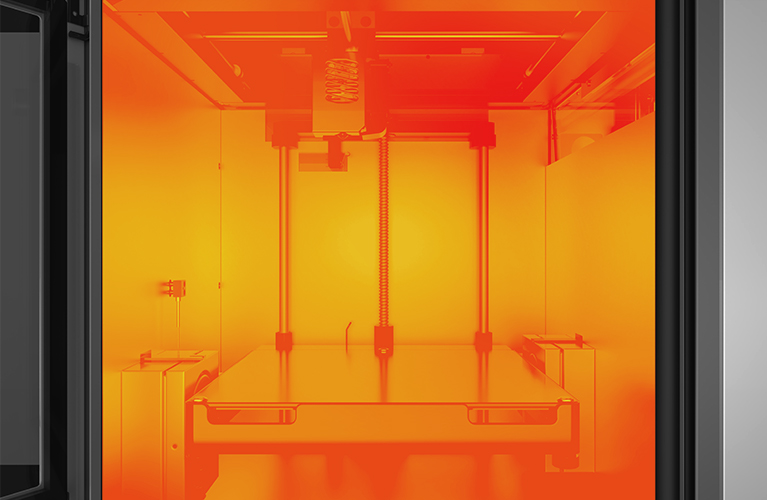

Advanced Temperature Capabilities

The Funmat HT is equipped with a high-performance single-extruder capable of reaching temperatures up to 450°C. Its closed, heated print chamber maintains a steady temperature of up to 90°C, ensuring optimal conditions for printing with high-performance materials like PEEK, PEI, and PPSU. With a heated bed that reaches up to 160°C, the Funmat HT minimizes warping and produces durable, mechanically strong parts, even for complex geometries, making it ideal for engineering and industrial applications.

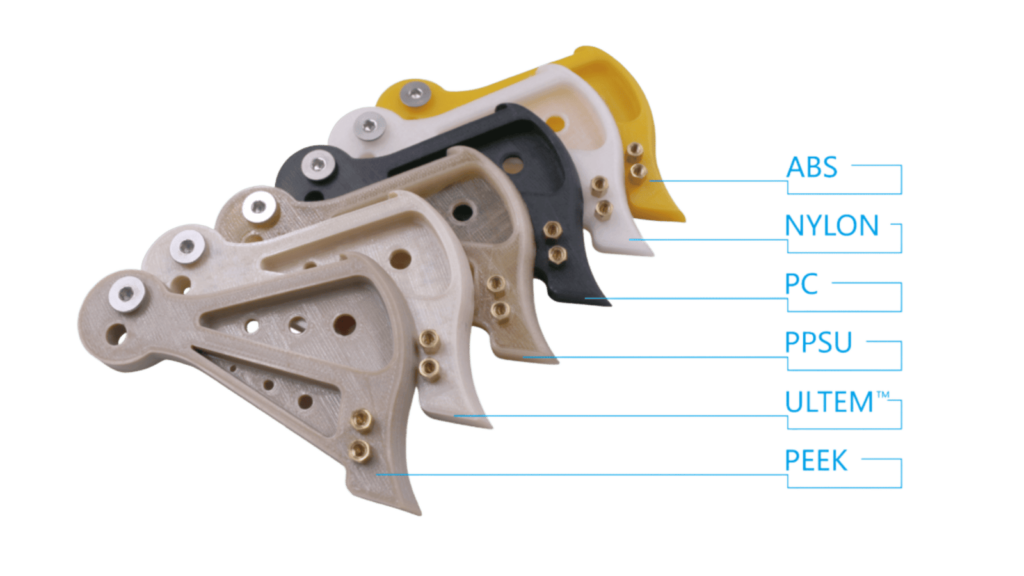

Materials That Drive Performance

The Intamsys Funmat HT is designed to print with a wide variety of high-performance materials, making it a top choice for industries such as aerospace, automotive, medical, and engineering. This 3D printer supports advanced engineering-grade polymers like PEEK, PEKK, PPSU, and carbon fiber composites, all known for their high strength, heat resistance, and durability. These materials are essential for creating parts that require superior mechanical properties and can withstand extreme conditions. Whether you’re prototyping or manufacturing end-use parts, the Funmat HT delivers consistent, reliable performance with high-temperature, high-strength materials.

Precision and Performance for Demanding Applications

When precision and material performance are paramount, the Intamsys Funmat HT is the ideal solution. Engineered to meet the high standards of industries such as aerospace, automotive, medical, and research, this 3D printer consistently delivers high-quality, functional parts that meet stringent industry requirements. Its advanced thermal system and robust build ensure both accuracy and reliability, making it perfect for prototyping and low-volume production where superior material properties and precise geometric accuracy are crucial.

Meet The Funmat HT

Key Features of the Funmat HT

High-Temperature Capabilities

Equipped with a 450°C all-metal hotend, 160°C heated build plate, and a 90°C heated chamber, the Funmat HT is designed to print advanced engineering-grade materials like PEEK, PEKK, and PPSU with ease.

Auto-Bed Leveling

The built-in automatic bed leveling feature ensures precise calibration before each print, leading to improved first-layer adhesion and higher print success rates.

Swappable Nozzles

The Funmat HT supports swappable nozzles ranging from 0.1mm to 0.8mm, allowing for flexibility in print resolution and speed, depending on project needs.

Open Material System

The printer offers an open material system, enabling compatibility with a wide range of 1.75mm filaments, from standard materials like ABS and PLA to high-performance thermoplastics.

Advanced Thermal Insulation

A fully enclosed, insulated build chamber retains heat efficiently, maintaining a stable environment to reduce warping and improve layer adhesion, especially when printing high-temperature materials.

Versatile Applications

Suitable for a wide array of industrial applications, the Funmat HT excels in aerospace, automotive, medical, and engineering fields, where the combination of strong mechanical properties and heat resistance is essential.

INTAMSYS FUNMAT HT Specs

| Assembly | Fully-assembled |

| Bed leveling | 3-Point Automatic Leveling, Manual Leveling |

| Chamber temperature | 90°C (320°F) |

| Closed print chamber | Yes, fully enclosed |

| Compatible with 3rd party filaments? | Yes an open material system |

| Display | LCD touch screen |

| Extruder type | Single |

| Filameter diameter | 1.75 mm |

| Frame | Aluminum |

| Manufacturer | Intamsys |

| Manufacturer country | China |

| Max. extruder temperature | 842 °F / 450 °C |

| Max. heated bed temperature | 320 °F / 160 °C |

| Max. print speed | 300 mm/s |

| Nozzle size, mm | 0.1, 0.25, 0.4, 0.6, 0.8 and more |

| Outer dimensions millimeters (xyz) | 530 x 490 x 645 mm |

| Printable material(s) | PEEK, PEI, PEI Blends, PPSU, PA/CF, PC, PC Alloys, PA, ABS, Carbon Fiber-Filled, Metal-Filled, Fiberglass-Filled, Nylon, ASA, PETG, ESD-Safe, HIPS, TPU, PLA, PVA |

| Weight kg | 43 kg |

| Build volume | 260 x 260 x 260 mm |

| Min. layer height | 50 Microns |

| Technology | FFF FDM |

Revolutionize Your Workflow with INTAMSUITE NEO

The all-new INTAMSUITE NEO slicing software is a game-changer for additive manufacturing. Designed to streamline your 3D printing experience, this powerful platform offers automated slicing for model design and repair, enabling users to simplify complex projects effortlessly.

INTAMSUITE NEO is not just a slicing tool—it’s an all-in-one collaborative platform that brings together online monitoring and process optimization. With its intelligent path planning algorithms, it optimizes print paths for maximum efficiency and quality, reducing material waste and improving overall production times.