AXE-B11 3D Scanner

Enhanced Precision in 3D Automotive Scanning

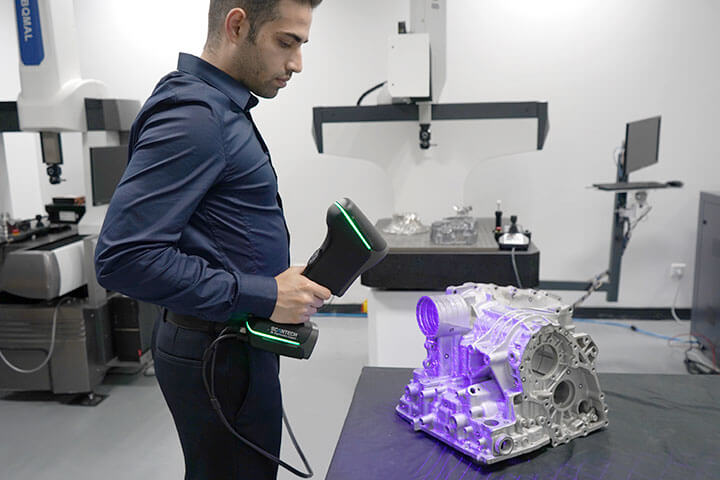

Leverage cutting-edge photogrammetry technology integrated within the AXE-B11 scanner to achieve unprecedented volumetric accuracy up to 0.020 mm/m and point accuracy up to 0.020 mm. Without additional devices, this system is specifically engineered for professional-grade 3D scanning of large volumes, such as automotive interiors and assemblies. Experience efficiency and precision in one powerful package. This scanner is a game changer in automotive manufacturing, perfect for quality control, reverse engineering, and design optimization.

Book a free demo or consultation of this product:

-Talk to a 3D expert

-See Scantech in action

-Be assured that AXE-B11 3D Scanner fits for you

Streamlining Production with High-Speed 3D Scanning

Harness the power of ultra-fast scanning with the AXE-B11, capable of recording up to 1,300,000 measurements per second. This remarkable speed streamlines the measurement process of large volumes, significantly reducing both time and labor costs in production environments. With a generous scanning area of 550 mm by 600 mm, the AXE-B11 requires minimal markers to complete scans, ensuring smooth and continuous operations. Ideal for complex geometries and intricate designs, this scanner delivers high fidelity data with exceptional speed and accuracy. It’s an indispensable tool for sectors demanding precise dimensional quality control, such as automotive and aerospace manufacturing.

One-Button Start

Diverse Accessories

Easy Programming

Manual Operation Supported

Safety Guard

Dual-Mode Flexibility

The AXE-B11 is equipped with 11 crossed blue lasers plus an additional blue laser line, offering a high-efficiency mode for extensive, large-scale projects and a single line mode tailored for intricate details such as deep holes and dead angles. This dual-mode functionality allows for versatile application, ensuring both broad coverage and precision detail in challenging areas, making it ideal for various engineering and quality assurance tasks.

The flexibility provided by the double scanning mode reduces the need for multiple setups, streamlining the scanning process and enhancing productivity. Moreover, this technology ensures that even the most difficult-to-reach areas are accurately captured, providing reliable data for complex analyses.

Learn More About The AM-DESK

Adaptive Configuration for Diverse Engineering Needs

The AXE-B11 3D scanner adapts seamlessly to various measurement challenges by integrating with an accurate reference bar and the comprehensive Helpers engineer kit. This modular approach allows engineers to tailor the scanning setup to specific project requirements, enhancing both flexibility and precision in capturing data.

Whether for small, intricate components or large industrial assemblies, the AXE-B11 provides the tools necessary for precise and efficient 3D measurement. Its versatility extends to a wide range of industries including automotive, aerospace, and manufacturing, ensuring optimal performance under diverse operating conditions. The scanner’s compatibility with various accessories also means it can be quickly reconfigured for new tasks, minimizing downtime and maximizing productivity.

AXE-B11 Tech Specs

| Accuracy | Up to 0.020 mm |

| Measurement rate | Up to 1,300,000 measurements/s |

| Laser source | 11 blue laser crosses with 1 extra blue laser line |

| Scanning area | Up to 550 mm x 600 mm |

| Scanning area with photogrammetry | 2500 mm x 3000 mm |

| Laser lines in total | 41 |

| Laser class | CLASS II (eye-safe) |

| Resolution | 0.025 mm |

| Volumetric accuracy with out extra device | 0.020 mm + 0.035 mm/m |

| Stand-off distance | 300 mm |

| Depth of field | 500 mm |

| Depth of field with photogrammetry | 2500 mm |