Artec Metrology Kit

Precision Inspection Made Simple

The Artec Metrology Kit transforms the inspection of complex components like aircraft parts, marine vessels, and wind turbines into a streamlined and dependable process. By delivering exceptionally accurate datasets, it ensures high confidence in inspections where repeatability is crucial.

The Kit’s photogrammetry data can be effortlessly integrated into your existing workflows, allowing for detailed comparisons with 3D meshes and CAD models, as well as highly accurate distance measurements. Additionally, its robust performance in challenging environments, such as when parts are in motion or on unstable surfaces, guarantees consistent precision throughout every stage of production.

Book a free demo or consultation of this product:

-Talk to a 3D expert

-See Artec in action

-Be assured that Artec Metrology Kit fits for you

Detailed Deformation Analysis with Unmatched Precision

The Artec Metrology Kit excels in deformation analysis, offering a powerful tool for assessing material distortions under various conditions. With its high-precision optical measurements, you can accurately monitor geometric changes in objects such as storage tanks, vehicle components, and design prototypes.

The Kit’s rapid acquisition capabilities are ideal for environments where quick and reliable data is essential, such as climate chambers or high-stress testing setups. Its portability and straightforward workflow allow for efficient analysis even in extreme conditions, ensuring you receive precise, actionable insights into material behavior and deformation.

Broad Spectrum Applications of the Artec Metrology Kit

The Artec Metrology Kit is a pivotal tool in transforming precision measurement across diverse industries. From automotive manufacturing to aerospace engineering, this kit provides crucial data that enhances quality control, boosts research and development efforts, and ensures the accuracy of complex assemblies in high-stakes environments. Below, we explore how this state-of-the-art technology is applied in different sectors to meet their unique demands for precision and reliability.

Aerospace

The Metrology Kit is extensively used by organizations in the fields of astronomy, defense, and space across Germany and Japan. It offers high-accuracy measurements critical for deformation analysis of satellite antennas.

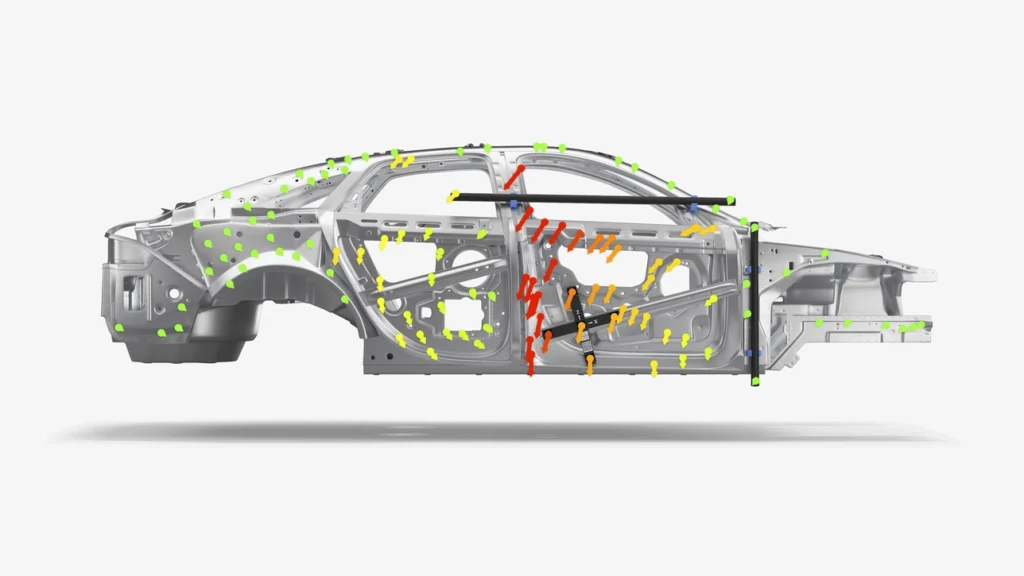

Automotive Industry

A major car manufacturer in Germany utilizes the Metrology Kit for quality control purposes. It is instrumental in analyzing the positions of welding studs on every fourth chassis within the production line.

Research and Development (R&D)

In the realm of autonomous driving, the Metrology Kit plays a crucial role in sensor placement accuracy. It helps major automotive companies determine the precise positions of sensors on vehicle bodies, ensuring they are correctly integrated within the car's coordinate system.

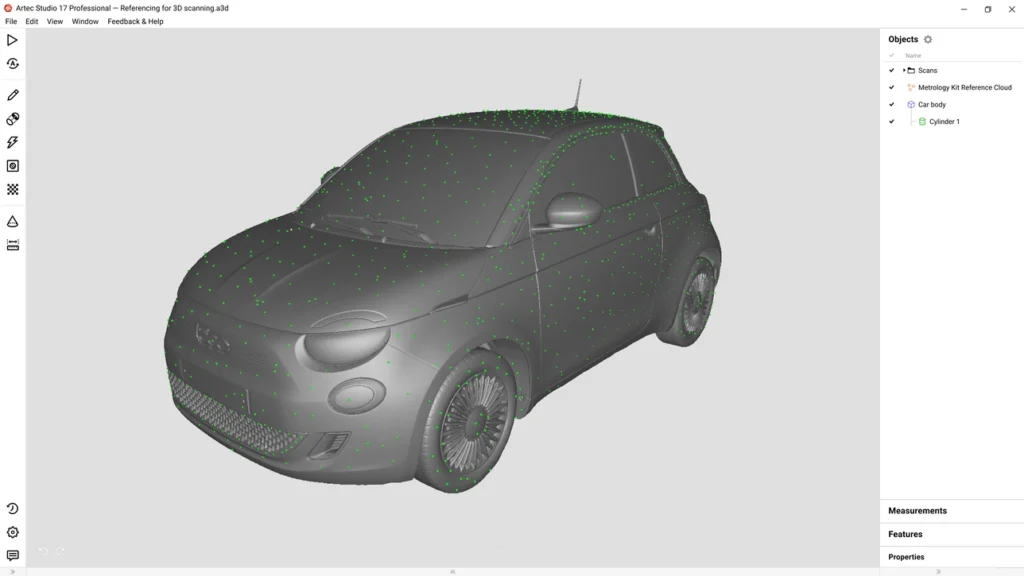

Enhanced 3D Scanning Accuracy Through Effective Referencing

The Artec Metrology Kit significantly elevates 3D scanning performance by providing precise referencing for enhanced accuracy over distances. By combining the dense point cloud data from the Metrology Kit with the high-resolution output of 3D scanners, you can achieve superior volumetric accuracy and minimal accumulated error.

This synergy allows for detailed capturing of smaller elements within larger objects, ensuring both high resolution and precision. The Kit’s optical measurements create a reliable reference framework, making it possible to extend the capabilities of small to medium-sized scanners and obtain detailed, accurate results across extensive areas.

Meet The Artec Metrology Kit

Maximizing the Utility of the Artec Metrology Kit

To fully leverage the Artec Metrology Kit, begin with meticulous object preparation by placing targets, reference crosses, and scale bars accurately around the object to ensure they remain fixed relative to it throughout the process. The capture phase involves systematically taking photos from multiple angles to create a comprehensive dome of images around the object, capturing each target multiple times. During processing, import these images into Artec Studio or your preferred photogrammetry software, where the Metrology Kit plugin facilitates the generation of a detailed target cloud. Finally, in the reporting phase, utilize the resultant point cloud data for precise deformation analysis, flatness inspection, and dimensional measurements to inform critical engineering decisions, ensuring optimal outcomes in your projects.

Artec Metrology Kit Technical Specs

| Specifications | Professional | Entry |

|---|---|---|

| Accuracy | ||

| Length measurement accuracy | MPE* | 0.015 mm + 0.015 mm × Length diagonal [m] | 0.025 mm + 0.025 mm × Length diagonal [m] |

| Point-based measurement accuracy | 0.002 mm + 0.005 mm/m (RMS) 0.003 mm + 0.007 mm/m (3 sigma) |

0.004 mm + 0.006 mm/m (RMS) 0.005 mm + 0.009 mm/m (3 sigma) |

| Volumetric accuracy combined with 3D scanners | ||

| Artec Leo/Artec Eva | 0.115 mm + 0.015 mm/m | 0.125 mm + 0.025 mm/m |

| Artec Space Spider | 0.065 mm + 0.015 mm/m | 0.075 mm + 0.025 mm/m |

| Camera | ||

| Sensor unit | Canon EOS R | Canon EOS 6D |

| Lens | 28 mm AICON metric wide-angle lens | 28 mm AICON metric wide-angle lens |

| Camera resolution | 30.3 megapixels (6720 × 4480) | 20.2 megapixels (5472 × 3648) |

| Field of view (FoV) | 65 × 46° | 65 × 46° |

| Illumination | White-light flash | White-light flash |

| Speed | Up to 8 images per second | Up to 4 images per second |

| Viewfinder | Diopter | Diopter |

| Wireless data transfer | Optional | Not supported |

| Power supply | Li-ion battery | Li-ion battery |

| Packaging | ||

| Dimensions | 215 × 120 × 140 mm | 245 × 110 × 150 mm |

| External dimensions of transportation box | 520 × 430 × 250 mm | 870 × 230 × 170 mm |

| Sensor weight | 1.7 kg / 3.7 lb | 1.4 kg / 3 lb |

| Weight of transportation box including system | Approx. 12 kg / 26.5 lb | Approx. 7.7 kg / 17 lb |

| Storage | Robust case with trolley | Robust case |

| Other specs | ||

| Recommended operating temperature | +5 to +45°C | +5 to +45°C |

| Conformity | CE, RoHS | CE, RoHS |

| Calibration and certification | DAkkS certificate for the complete measuring system including scale bars and sensor DAkkS-calibrated scale bars: 1 × 1430 mm, 1 × 830 mm VDI 2634 page 1 certified system |

DAkkS certificate for the complete measuring system including scale bars and sensor Factory-calibrated scale cross 800 Opt. VDI 2634 page 1 certified system |

Artec 3D Software

Artec Studio 18

Artec Studio 18 takes 3D scanning to the next level, offering the most advanced software in the industry for processing and creating professional-grade 3D models.

Leverage cutting-edge features like Smart Fusion, which intelligently merges multi-resolution scan data from different Artec scanners, ensuring you capture the finest details and large areas with unmatched precision. The AI-powered Autopilot Mode guides you through the post-processing steps, automatically selecting the best algorithms to deliver high-quality, lifelike 3D models faster than ever.

With a wealth of additional tools at your disposal, from enhanced texture rendering to instant deviation analysis, you maintain full control over every aspect of your project, achieving results that exceed expectations.

With the intelligent Autopilot mode, you can get the greatest results in no time.

For your scan data, a photorealistic texture is available.

With the intelligent Autopilot mode, you can get the greatest results in no time.

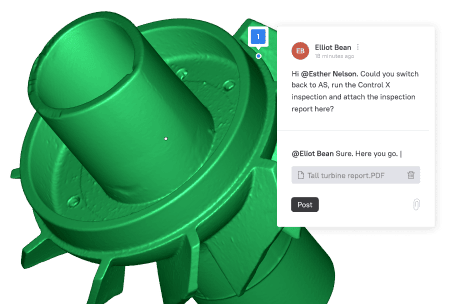

ARTEC CLOUD ALLOWS YOU TO ACCESS 3D DATA FROM ANYWHERE.

Collaborate, view, and process on the go

Always stay connected when working remotely

Work with 3D data on your browser