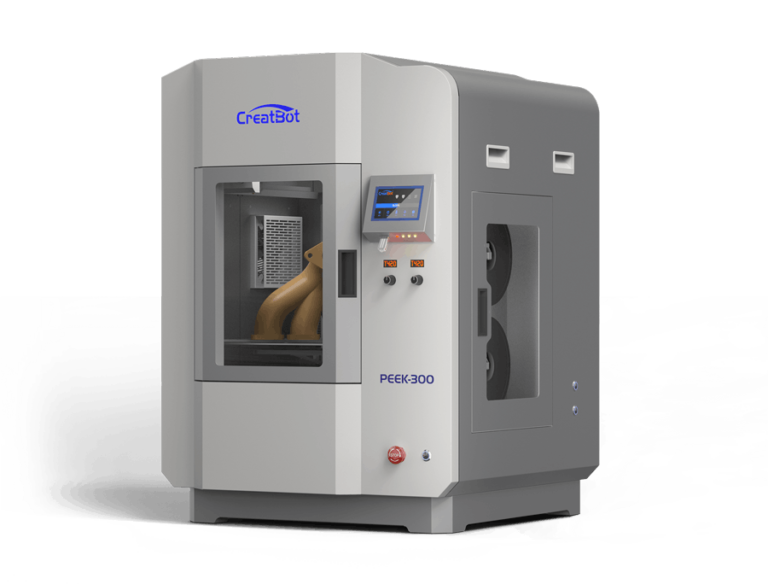

CreatBot PEEK-300

The Creatbot PEEK-300 is a cutting-edge industrial 3D printer designed for high-performance applications requiring robust materials such as PEEK and Ultem. With a strong focus on precision and durability, the PEEK-300 offers a comprehensive set of features, including 500°C dual extruder nozzles, a water cooling system, and a heated chamber, to deliver flawless prints even with the most demanding engineering materials.

Its large build volume and advanced thermal management system, including the patented Direct Annealing System (DAS), allow users to produce large, high-quality prototypes and functional parts with minimized warping or cracking. The PEEK-300 is ideal for industries such as aerospace, automotive, medical, and military, where precision and material performance are paramount.

This 3D printer empowers professionals to achieve reliable, high-quality results on a wide range of materials, all at an affordable price point.

Direct Annealing System (DAS)

The Direct Annealing System (DAS) by CreatBot is a groundbreaking technology, the first of its kind globally. This innovative process allows for real-time control of annealing during printing, ensuring the highest quality parts with no warping or cracking, even for large functional materials. (Exclusively patented and available only through CreatBot.)

Direct Annealing System (DAS) Features

- Instantaneously: Finished during the printing process, no need for secondary treatment in the oven.

- Completely: The annealing process applies to every extruded filament, not the whole printed model. The internal structure of the whole model cannot be fully crystallized or will deform in the oven.

Book a free demo or consultation of this product and get your sample parts printed:

-Talk to a 3D expert

-See Creatbot in action

-Be assured that PEEK-300 fits for you

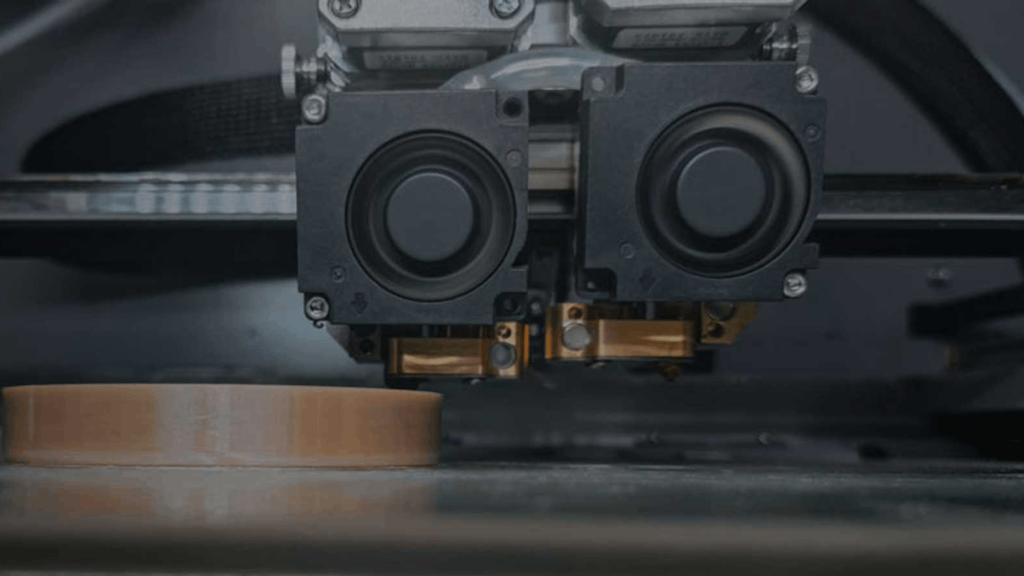

Intelligent Dual Extruder System at 480°C

The PEEK-300 features CreatBot’s innovative Smart Auto-Rising Dual Extruders. This cutting-edge technology includes water cooling, the DAS system, and auto-rising extruders. With dual nozzles capable of reaching temperatures up to 480°C, the PEEK-300 can handle any 3D printing material available. It is the optimal choice for working with a wide range of polymer materials.

Additive Materials That Make A Difference

CreatBot has partnered with the industry’s top material developers to deliver the best in performance and quality. Composite materials like carbon-filled nylon, or flame retardant material like ULTEM are very popular materials we offer. PEEK and many other

Strict Requirements Call For High Performance

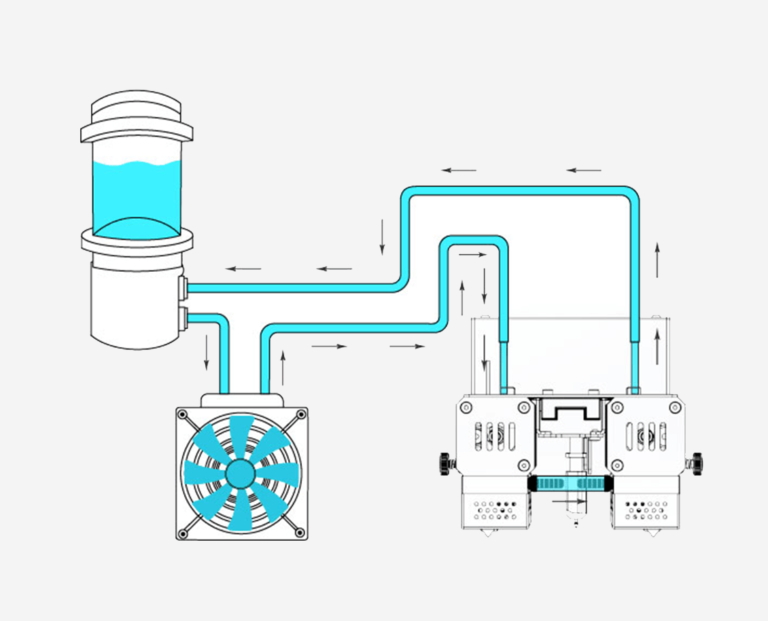

Advanced Heat Control and Cooling System for Precision Printing

The Creatbot PEEK-300 is designed with advanced technologies to handle high-temperature 3D printing, making it ideal for engineering-grade materials. It features a powerful heat control system with a 500°C hotend, a 200°C heated bed, and a 120°C heated chamber, ensuring precise temperature management for optimal printing. The patented Direct Annealing System (DAS) enhances print quality by minimizing warping and cracking, especially in large-scale prints. The innovative cooling system, which uses both liquid and air-pump cooling, further helps regulate temperatures, delivering consistent results even with complex parts.

Advanced Cooling Technology

The cooling system is a critical component for maintaining the optimal thermal environment during high-temperature printing. It incorporates two sophisticated mechanisms:

- Liquid cooling, where circulating liquid ensures sustained, efficient cooling over long print sessions.

- Air pump cooling, which draws in cool air from outside the printer, effectively replacing the hot air inside the chamber. This dual-system design keeps the printing process stable, reducing risks of warping or overheating, and ensuring high-quality output, even with temperature-sensitive materials.

Meet The Creatbot PEEK 300

Creatbot PEEK-300 Specs

| Printing | |

| Build Volume | Single Extrusion: 300*300*400 mm Dual Extrusion: 240*300*400 mm |

| Filament Diameter | 1.75mm |

| Number of Nozzles | Dual Extruder |

| Nozzle Diameter | 0.4mm (0.3~1.0mm optional) |

| Filament Compatibility | Engineering Plastics: PLA, ABS, ASA, PC, Nylon, PETG, PVDF,Carbon Fiber; High temperature Material: UltraPA, UltraPA-GF, UltraPA-CF, PPSU, PEI(ULTEM); Ultra-performance material: PEEK,CF-PEEK (Carbon fiber), GF-PEEK (glass fiber), PEKK, etc. |

| Special Function | |

| Outage Restored | Save data when power is off |

| Filament Detection | Pause printing when filament run out |

| Direct Annealing System (DAS) | Annealing process is instant controllable during printing. It aims to provide best quality parts in one time without warping and cracking printing of big size functional materials. |

| Heat insulation | Triple heat insulation |

| Emergency stop switch | Support emergency stop |

| High temperature accessories | High temperature resistance motors, linear rails, belts and circuits to ensure long time high temperature printing. |

| Temperature | |

| Nozzle Max. Temperature | 480℃ |

| Chamber Temperature | 120℃ |

| Platform Max. Temperature | 200℃ |

| Direct Annealing Temperature | 0~400℃ |

| Mechanical | |

| Cooling | Air pump cooling & water cooling |

| Platform | PCB aluminum + PEEK print board |

| Positioning Precision | X Y axis 0.0127mm, Z axis 0.00125mm |

| Extruder | Directly Drive |

| Machine Construction | Fully enclosed hot chamber |

| Bed Leveling | Manually/Automatic |

| Electrical | |

| Input Power | 200V~240V, 20A |

| Rated Power | 4600W |

| Screen | 4.3” full color touch screen, multi-language |

| Print Method | USB Connectivity/USB Disk |

| Size & Weight | |

| Machine Size | 720*700*941.5mm |

| N.W | 110 kg |

| Packing Size | 820*720*1080mm |

| G.W | 145 kg |

| Software | |

| Software | Creatware, Simplify3D, Cura, Slic3r |

| Operating Systems | Windowsall, macOS |

| Print File Type | STL, OBJ, AMF, Gcode |