High-temp build chamber allows for accurate parts every time

1 Year Warranty

Stong materials that can handle engineering tasks in many applications

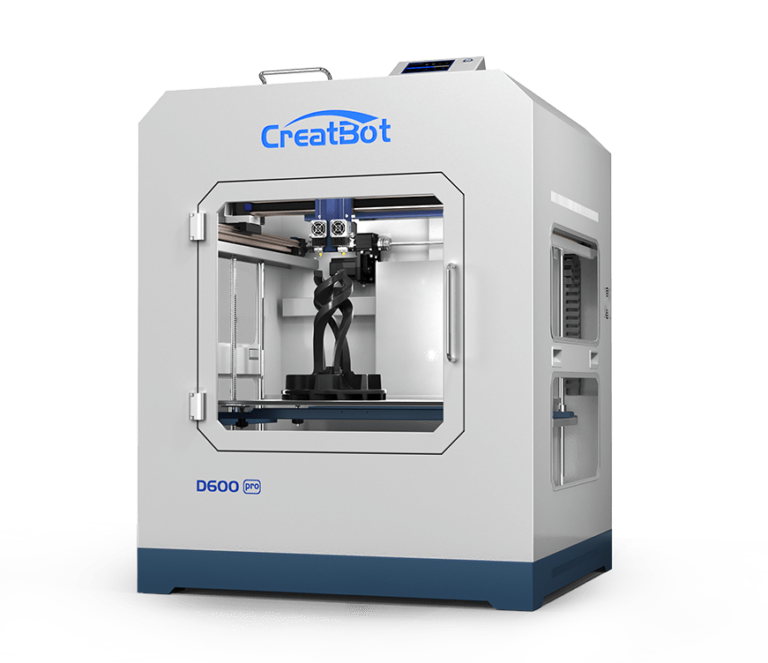

The CreatBot D600 Pro was created to make industrial 3D printing of large-scale objects and prototype as easy as possible. It is embedded with many advanced technology for ultra big, impressive, prints. It will be your best choice with no doubt, If you are looking for an industrial large scale 3D printer for prototype and engineering-grade materials.

Affordable price plus a build size 600*600*600mm, make it the best choice to your business. Trusted by 2000+ professional clients.

High-temp build chamber allows for accurate parts every time

Stong materials that can handle engineering tasks in many applications

-Talk to a 3D expert

-See Creatbot in action

-Be assured that D600 Pro fits for you

The D600 Pro offers an impressive print size of 600 x 600 x 600 mm. In the photo, you can see part of the quality inspection area for our large-format 3D printers, where mass production ensures consistent high quality. (Learn more about the massive D1000 3D printer in the center of the photo.

The D600 Pro features fourth-generation 1.75mm dual extruders and hotends. The left extruder, equipped with a 260°C hotend, is capable of printing with materials such as PLA, ABS, PC, Nylon, Carbon Fiber, and Flexible filaments. The right extruder, with a 420°C hotend made of martensite steel, is designed for high-performance materials. Both hotends are replaceable, offering enhanced versatility for various applications.

CreatBot has partnered with the industry’s top material developers to deliver the best in performance and quality. Composite materials like carbon-filled nylon, or flame retardant material like ULTEM are very popular materials we offer. PEEK and many other

CreatBot supports the entire product creation process, from R&D to production and quality control. It excels in rapid prototyping, product design, and manufacturing. Speak with a Rev1 specialist to discover how CreatBot can help accelerate your product development and time to market.

This feature ensures that if there’s a power outage, the printer can resume exactly where it left off without ruining the print. Filament detection also monitors the status of filament, pausing prints when the material runs out, reducing wasted time and materials.

This feature allows the printer to maintain optimal temperatures for both the chamber and filament, ensuring consistent material flow and reducing moisture absorption, which is critical when printing with materials like ABS, nylon, and others sensitive to environmental conditions.

These components improve precision and stability during the printing process. Linear rails reduce resistance, enabling smoother and more accurate movements, while the servo motors add more controlled and powerful motion, essential for large prints.

The auto-leveling platform ensures that the print bed is perfectly leveled before starting a print. This automatic adjustment helps in achieving flawless first layers, which is vital for large-scale prints to avoid errors.

The integrated HEPA filter captures fine particles generated during the printing process, ensuring a cleaner and safer working environment, especially when printing with materials that emit fumes or particles.

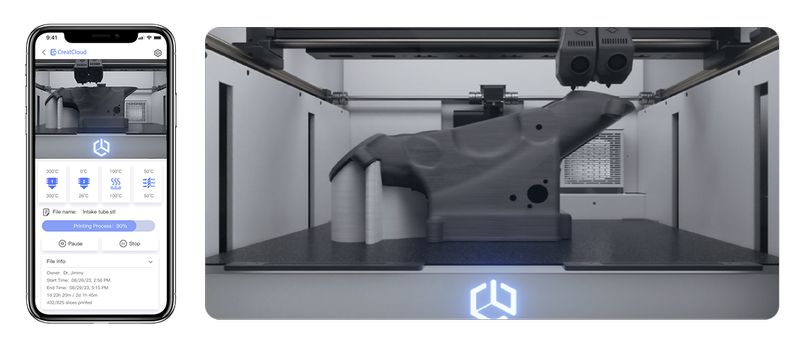

This feature allows for remote monitoring of print progress via a smartphone app, enabling users to control the printer, pause prints, and check real-time status from anywhere, making the printer more user-friendly and accessible.

| Printing | |

| Print Technology | Fused Deposition Modeling(FDM) |

| Build Volume | Single Extrusion: 600*600*600 mm Dual Extrusion: 540*600*600 mm |

| Number of Nozzles | Double |

| Layer Resolution | 0.05 mm |

| Filament Diameter | 1.75 mm |

| Filament Compatibility | PLA, ABS, Carbon Fiber, Wood, Nylon, PC, PETG, HIPS, PP, Flexible, TPU, PVA, etc. |

| Nozzle Diameter | 0.4mm (0.3 0.5 0.6 0.8 1.0mm) |

| Print File Type | STL, OBJ, AMF, Gcode |

| Temperature | |

| Ambient Operating Temperature | 15 ℃~32 ℃ |

| Max. Nozzle Temperature | 420 ℃ |

| Max. Bed Temperature | 100 ℃ |

| Max. Chamber Temperature | 70 ℃ D600 Pro |

| Filaments Drying Temperature | 45 ℃/65 ℃ D600 Pro |

| Speed | |

| Best Printing speed | 45 mm/s |

| Max. Printing speed | 120 mm/s |

| CreatBot D600 Pro Size & Weight |

| Product Dimensions & Weight | 915*845*1085mm 125kg |

| Packing Size & Weight | 940*1010*1320mm 165kg(Pallet) |

| Mechanical | |

| Construction | Power-Coated Steel, Aluminum Casting for Motion Components, POM |

| Build Plate | Aviation aluminum plate |

| Build Plate Leveling | Factory Leveled, Adjust Manually Automatic D600 Pro |

| Extruder | Directly Drive |

| Stepper Motors | 1.8° Step Angle with 1/16 Micro-stepping |

| X Y Positioning Precision | 5.08 μm |

| Z Positioning Precision | 1.25 μm |

| Electrical | ||

| Power Requirements | ||

| 200V-240V / 50-60Hz ( D600 / D600 Pro ) | ||

| Screen | 4.3” Touch Screen with Multi-language | |

| Rated Power | D600: 1500W, D600 Pro: 4900W | |

| Storage Media | USB Disk | |

| Connectivity | USB | |

| Software | |

| Software | CreatWare, Simplify 3D, Cura, Slic3r, etc |

| Supported File Types | STL,OBJ,AMF |

| Operating Systems | Windowsall, macOS |